Alumina Products

- Home

- Alumina Products

Alumina Products & Applications

APPLICATIONS AND DIFFERENT TYPES OF ALUMINA WE SERVE,

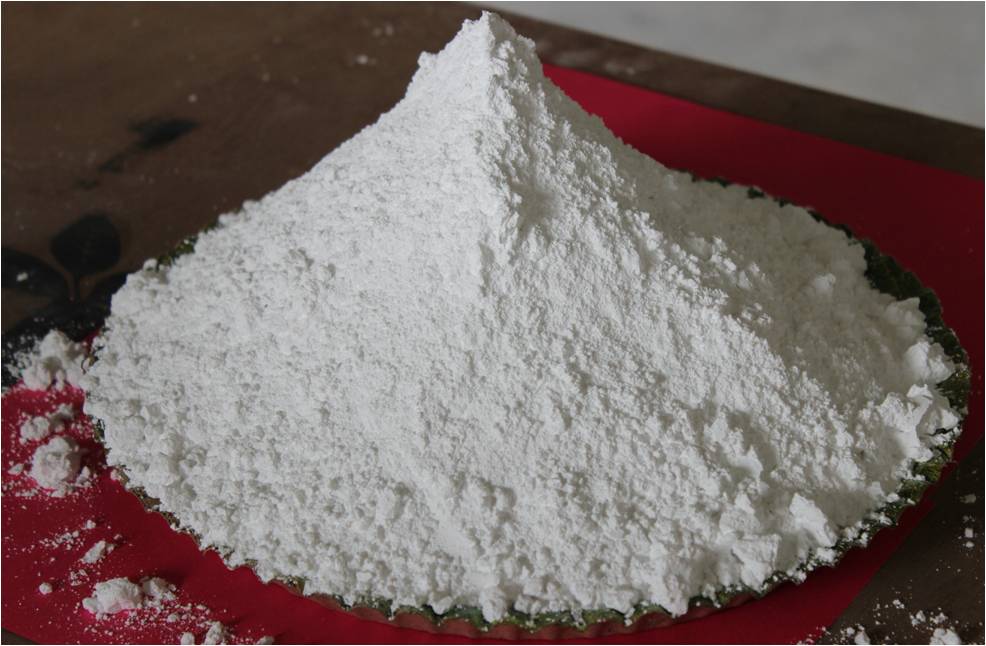

Calcined alumina is a high-purity form of aluminum oxide produced through the thermal treatment of aluminum hydroxide. It is a versatile material used in a variety of industries, including ceramics, refractories, abrasives, catalysts, and polishing compounds. This website provides a comprehensive guide to calcined alumina production, including its properties, applications, and production process.

Coarse Alumina: Coarse alumina is alumina with a larger particle size, typically ranging from 10-50 microns. It is often used in applications where a larger particle size is desirable, such as in refractory materials, thermal insulation, and abrasives.

Ground Alumina: Ground alumina is alumina that has been ground into a fine powder with a particle size typically ranging from 1-10 microns. It is often used in the production of ceramics, coatings, and polishing compounds.

Fine Alumina: Fine alumina is alumina with a particle size typically ranging from 0.5-5 microns. It is used in various applications such as electronics, polishing, and catalysts.

Milled Alumina: Milled alumina is alumina that has been milled to a specific particle size distribution. It can range in particle size from coarse to fine and is often used in applications such as abrasives, polishing, and ceramics.

Low Soda Alumina: Low soda alumina is alumina with low sodium oxide content, typically less than 0.1%. It is often used in high-temperature applications such as refractories and ceramics where sodium can cause issues such as spalling or cracking. Low soda alumina has a higher purity compared to regular alumina.

Overall, the differences between these types of alumina are based on their particle size and purity, which can affect their suitability for specific applications.

We manufacture specialty alumina to satisfy your needs.

TYPICAL CHARACTERISTICS OF CALCINED ALUMINA:

- High Purity

- High Temperature Stability

- Abrasion Resistance

- Electrical Insulation

- Chemical Inertness

- High Compressive Strength

- Low Thermal Expansion

Industries We Serve

- Polishing Aluminas for,

_ Automotive polishing

_ Ophthalmic polishing

- Ceramic Applications

_ Insulators

_ Tiles and Sanitary wares

_ Tableware Industries

_ Bioceramics

_ High performance ceramics

- Refractory Applications

_ Bricks

_ Lining and coating

_ Saggers/ Setters

_ Setter wash

- Glass Industries

_ Float Glass

_ Bottle Glass

- Raw Material Manufacturing Industries

_ Glazes and Frits

_ Pigments and glaze compounds

_ Additives and filler

_ Pharmaceutical